In the realm of custom apparel production, DTF transfers, or Direct-to-Film transfers, have revolutionized the way designs are printed on fabrics. This innovative method is known for its capability to deliver vibrant, long-lasting prints that cater to a variety of fabric types, providing unparalleled versatility. However, realizing the full potential of DTF transfers requires an understanding of critical factors such as heat press settings and fabric compatibility. As the industry continues to evolve, mastering DTF printing techniques becomes essential for achieving high-quality results that satisfy customer demands. In this guide, we will delve into the best practices for DTF transfers, ensuring your designs not only shine but also withstand wear over time.

When discussing direct-to-film print technology, known commonly as DTF printing, it’s important to recognize the significant impact it has made in the custom apparel landscape. This method facilitates the creation of striking, durable designs on various textile surfaces, making it a favorite choice for many garment decorators. Achieving the best possible results involves not just a high-quality print but also a thorough understanding of critical components, including the right heat press settings and the compatibility of different fabrics. As we explore the intricacies of DTF transfers, we will highlight effective strategies to enhance printing outcomes, ensuring your customized garments leave a lasting impression. Join us as we uncover essential practices that elevate the standard of your DTF printing efforts.

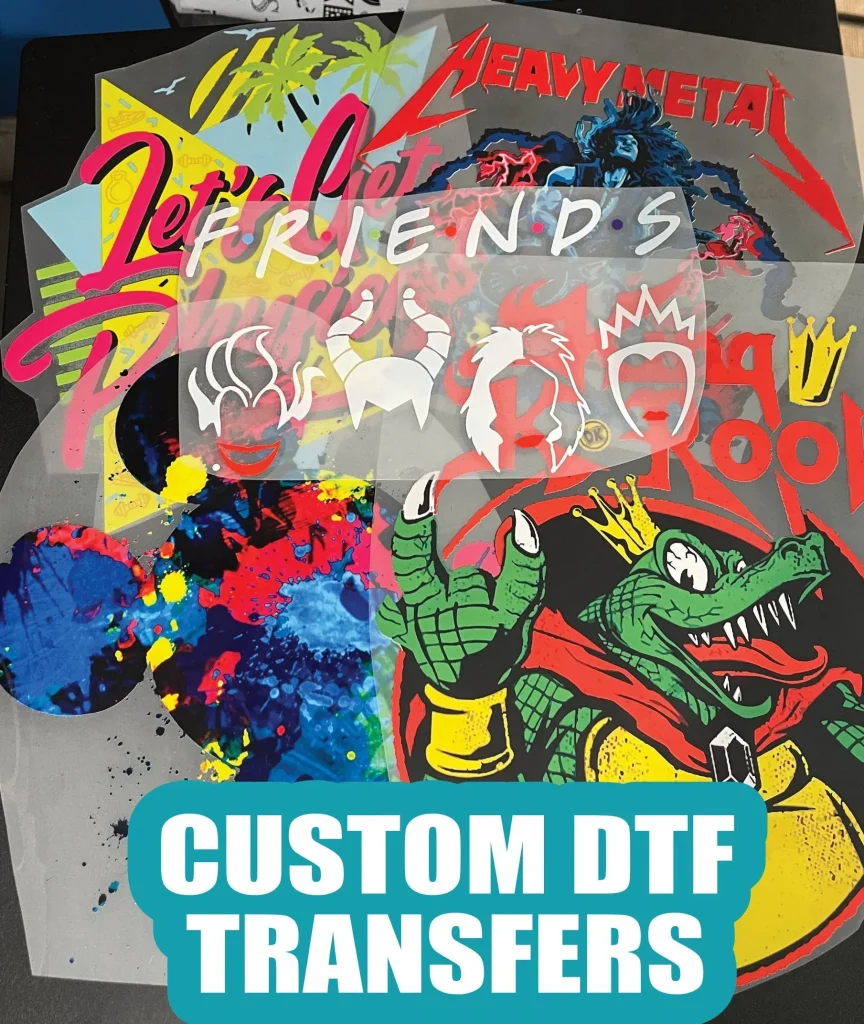

Understanding DTF Transfers: A Game-Changer in Custom Apparel

DTF transfers, or Direct-to-Film transfers, represent a revolutionary shift in the custom apparel industry. This innovative printing technique allows for stunning graphics to be transferred onto various fabrics with unmatched precision. What sets DTF apart is its ability to produce vibrant colors and intricate designs that remain durable wash after wash. This makes it ideal for small businesses and designers looking to create unique apparel that captures attention and endures over time.

Additionally, DTF printing opens up new possibilities for fabric compatibility. From 100% cotton to various blends, DTF can adhere effectively, broadening the range of fashion statements that can be made. Businesses can explore different materials confidently, knowing that with the right setup and practices, they can achieve high-quality results every time.

Material Selection for Optimal DTF Transfer Quality

Choosing the right materials is pivotal in the DTF transfer process. High-quality DTF transfer films are essential to achieving vibrant prints that last. Brands like Apreel and Crown are recommended for their consistent quality and reliability. These films are designed to work harmoniously with specialized water-based TPU inks, which enhance adhesive properties and color vibrancy, ensuring designs remain intact after multiple washes.

Further, it’s important to ensure compatibility between the film and inks used. Adhering to recommended combinations not only optimizes print quality but also ensures durability. For the best results, invest in top-tier materials and conduct regular testing to determine which combinations yield the best transfer outcomes.

Printer Calibration: The Backbone of Quality DTF Printing

Regular printer calibration is key to maintaining the integrity and quality of DTF printing. A properly calibrated printer prevents issues such as ink clogging and inconsistent color output, both of which can negatively impact your final products. With DTF transfers, having a printer that delivers sharp and clear imagery is not just a benefit but a necessity.

To achieve optimal results, set aside time for routine maintenance of your printing equipment. This includes cleaning printheads, checking ink levels, and calibrating color profiles to suit the specific needs of your designs. Ensuring that your printer operates at peak performance is an investment in the quality of your DTF transfers.

Mastering Heat Press Settings for Successful DTF Transfers

Heat press settings play a crucial role in the DTF transfer process. Accurate temperature and pressure settings are essential for ensuring the transfer adheres correctly to the fabric. A common guideline suggests setting your heat press to approximately 320°F (160°C) with firm pressure for around 10-15 seconds, but these parameters can vary depending on the specific products being used.

Consulting product guidelines is paramount for achieving the best results. Optimal press settings not only enhance the quality of the transfer but also improve its longevity, avoiding common issues such as peeling or fading. Careful monitoring of your heat settings can lead to spectacular, durable results for your custom apparel.

The Importance of Cooling in Post-Press Techniques

One often-overlooked aspect of the DTF transfer process is the cooling phase post-press. Allowing your transfer to cool completely before peeling off the film can make a significant difference in the final product’s quality. This simple step enhances the bond between the print and the fabric, which is crucial for maintaining the vibrancy and integrity of your designs.

Rushing the cooling process can lead to poor adhesion and premature wear of the transfer. By taking the time to let your designs cool effectively, you not only ensure a higher quality finish but also that your custom apparel withstands the test of time, preserving the investment you’ve made in your DTF printing setup.

Exploring Fabric Compatibility: Key to DTF Success

Fabric compatibility is pivotal when it comes to mastering DTF transfers. While many fabrics are suitable, 100% cotton typically provides the best results due to its superior ink adhesion properties. Understanding the unique characteristics of various fabrics can help you make informed decisions and achieve vibrant prints that resonate with your audience.

Testing different materials, such as polyester blends or specialty fabrics, is also crucial in determining how well your DTF transfers adhere. By experimenting with various textile types, you can expand your product offerings and ensure that every piece of custom apparel meets the high standards of quality that your brand promises.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a printing method used to create high-quality graphics for custom apparel. This technique involves printing designs onto a special film using inkjet printers. After printing, hot-melt adhesive powder is applied and then heated using a heat press to transfer the design onto fabric, ensuring durability and vibrant colors.

What are the best heat press settings for DTF printing?

For optimal DTF printing results, set your heat press to approximately 320°F (160°C) with firm pressure for about 10-15 seconds. These settings may vary depending on the specific film and ink used, so it’s important to refer to product guidelines to ensure the best transfer quality.

What materials are recommended for high-quality DTF Transfers?

To achieve high-quality DTF Transfers, it is crucial to select the right materials. Use high-quality DTF transfer films like Apreel or Crown, and ensure you are using water-based TPU inks, which enhance adhesion and color vibrancy, leading to more durable and vibrant prints on your custom apparel.

How does fabric compatibility affect DTF Transfers?

Fabric compatibility is essential for successful DTF Transfers. While blends can work, 100% cotton typically provides the best results due to its superior ink adhesion and overall print quality. Testing various fabric types is advisable to find the ideal match for your DTF printing projects.

Why is printer calibration important for DTF printing?

Regular printer calibration is critical in DTF printing as it maintains color accuracy and prevents printhead clogging. A calibrated printer ensures consistent ink flow, resulting in sharp and clear images for your transfers, which is fundamental for achieving a professional finish in your custom apparel.

What post-press techniques should be followed after applying DTF Transfers?

After using a heat press for DTF Transfers, allow the transfer to cool completely before peeling off the film. This technique helps to set the design better on the fabric, enhancing the print’s longevity and ensuring a high-quality finish for your custom apparel.

| Key Practices | Details |

|---|---|

| 1. Material Selection | Choose high-quality DTF transfer films and water-based TPU inks for vibrant and lasting designs. |

| 2. Printer Calibration | Regularly calibrate printers to ensure color accuracy and prevent printhead issues. |

| 3. Temperature and Pressure | Set heat press to 320°F (160°C) with firm pressure for 10-15 seconds, adjusting based on film and ink. |

| 4. Adhesive Powder Application | Apply adhesive powder evenly to create a strong bond and avoid peeling or fading. |

| 5. Post-Press Techniques | Allow transfers to cool completely before peeling to enhance durability and finish. |

| 6. Fabric Compatibility | Use compatible fabrics, with 100% cotton providing the best adhesion and quality. |

| 7. Quality Checks | Conduct test prints to identify issues and fine-tune settings before larger production runs. |

Summary

DTF Transfers have revolutionized the world of custom apparel by providing stunning prints that are both durable and vibrant. To truly maximize the quality of DTF transfers, several best practices must be adhered to, ranging from the selection of materials to the calibration of printers and the proper application techniques during the transfer process. Each step from choosing high-quality films and inks to ensuring the right temperature and pressure during pressing plays a crucial role in achieving excellent results. For anyone involved in the custom printing industry, understanding and applying these strategies will not only enhance the quality of prints but also distinguish their products in a competitive market, ensuring longevity and customer satisfaction.