DTF printing techniques have quickly gained popularity in the textile industry, redefining how designs are transferred onto fabrics. By harnessing the power of Direct to Film printing, creators can achieve vibrant and high-quality prints that stand out from the crowd. Understanding the best practices for DTF is crucial for anyone looking to produce stunning DTF designs that captivate their audience. In this article, we will explore essential DTF printing tips and techniques to enhance your process, ensuring your prints are both breathtaking and long-lasting. Join us as we unlock the full potential of DTF printing, transforming your creative visions into reality.

Exploring the world of Direct to Film printing techniques reveals an innovative method of applying intricate designs onto various fabrics. This advanced printing process uses a film transfer, combining high-quality inks with a precise application to generate stunning visual results. If you’re curious about effective strategies and tips that can elevate your fabric printing game, understanding essential components is key. With a focus on quality materials and meticulous design considerations, you can revolutionize your approach to creating stunning designs that resonate with your audience. Dive into this guide to discover how to perfect your printing art with comprehensive insights and best practices.

The Importance of Quality Materials in DTF Printing

In DTF printing, the choice of materials is paramount to achieving vibrant and long-lasting prints. Utilizing high-quality DTF films and premium inks can make all the difference in final output. Brands like Inktec and Adkins are established names in this space, known for their durable and reliable supplies. Investing in top-tier materials not only enhances the brightness of colors but also contributes to the overall durability of the prints, making them less susceptible to fading over time.

Moreover, using compatible inks that align with your printer’s specifications ensures smooth operation and avoids potential issues that could compromise the quality of your prints. For instance, DTF inks designed specifically for certain printer models can provide superior color saturation and clarity, enabling you to create stunning DTF designs that stand out in any market. Always prioritize quality when sourcing your supplies to lay a solid foundation for your printing projects.

Mastering Printer Calibration for Flawless Results

Achieving consistent color output in DTF printing heavily relies on proper printer calibration. By adhering to manufacturer guidelines for setting up color profiles and adjusting printer settings, you can ensure that the colors in your final prints closely resemble those in your original designs. Regular calibration also helps maintain the performance of essential components, such as heating elements, which are critical in the DTF printing process.

In addition, keeping a close eye on maintenance can prevent variations in color that might arise from a lack of calibration. By regularly checking and adjusting settings, you’ll minimize risks of unexpected discrepancies, leading to high-quality prints that reflect your artistic vision. Remember, the goal is to maintain a consistent and accurate color range, which enhances the appeal of your stunning DTF designs and builds customer trust.

To further enhance color accuracy, incorporating software that tracks and displays color profiles can be incredibly beneficial. Familiarizing yourself with color management practices will also assist in optimizing your DTF printing outcomes, allowing your designs to shine.

Design Considerations for Stunning DTF Prints

Creating exceptional designs for DTF printing requires a keen understanding of graphic design principles. Utilizing vector graphics is essential, as programs like Adobe Illustrator allow for scalable designs that maintain quality, regardless of size adjustments. This flexibility enables designers to implement intricate details that can truly captivate an audience when printed.

Additionally, being aware of how colors may display differently on screens compared to their printed versions is crucial. Conducting thorough tests of color separations can aid in better predicting how your designs will appear once executed on fabric. This pre-emptive step in your design process can save time, material, and frustration, leading to more professional and polished outcomes in your DTF projects.

Effective Pre-Treatment and Curing Techniques

The pre-treatment process is a critical step in DTF printing that significantly influences ink adhesion to fabrics. Properly treating your materials creates a conducive surface for the ink, leading to prints that are less likely to peel or crack over time. Treatments may vary depending on the type of fabric, so it’s vital to select the correct method that complements your materials for optimal results.

In conjunction with pre-treatment, curing prints at the proper temperatures and durations ensures that your designs are resilient against multiple washes and prolonged wear. This stage solidifies the ink’s bond to the fabric, maintaining vibrancy and detail. By paying close attention to these steps, you can enhance the durability and professional appearance of your DTF prints, making them appealing to consumers who demand quality.

Maximizing Design Potential with Pattern Placement

Understanding how to align patterns with various fabric types is essential for achieving impactful DTF prints. Each fabric behaves differently, and designs must be adjusted to accommodate textures and stretches. For instance, smooth fabrics might allow for seamless pattern application, while textured surfaces can require significant alteration for optimal results.

Taking the time to create test prints on actual fabric samples can greatly benefit pattern placement. By experimenting with different layouts and adjustments, you can refine your designs prior to full production, minimizing waste and ensuring the final products resonate well with your target market. This attention to detail sets the stage for stunning DTF designs that will truly catch the eye.

Enhancing DTF Designs with Special Effects

In a saturated market, standing out can be a challenge, but incorporating special effects into your DTF prints can elevate your work to new heights. Techniques such as metallic inks, glow-in-the-dark details, or textured finishes add a unique flair that can draw attention and increase the desirability of your designs. Customers are often on the lookout for something different, and these effects can effectively fulfill that need.

Experimenting with various special effects will not only enrich the visual appeal of your prints but also tap into creative potentials that differentiate your projects. Consider creating a signature style that combines several effects, making your work identifiable among competitors. By embracing these innovative techniques, you can take your DTF printing to the next level and captivate a broader audience.

Frequently Asked Questions

What is DTF printing and how does it differ from traditional methods?

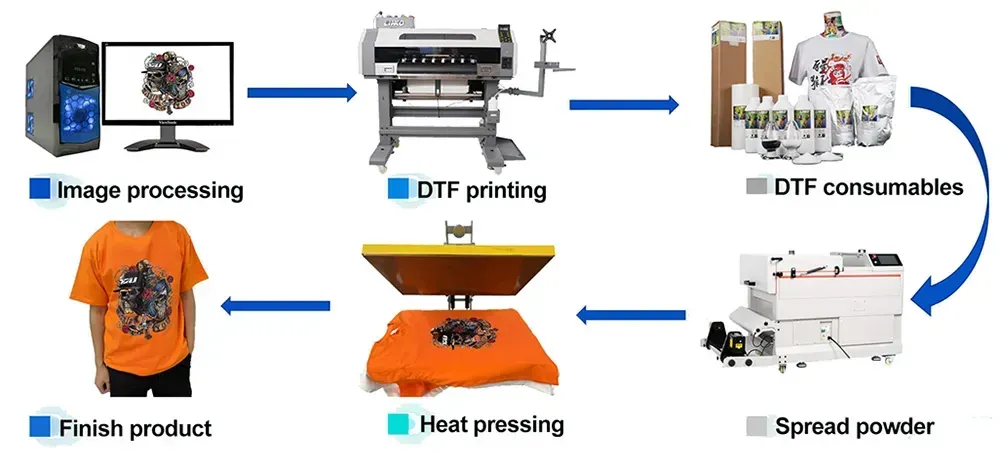

DTF printing, or Direct to Film printing, is a modern technique that utilizes pigment inks on heat transfer film, allowing for vibrant and detailed prints on a variety of fabrics. Unlike traditional screen printing, DTF enables intricate designs and color gradients, making it an ideal choice for producing high-quality, stunning apparel.

What are some best practices for DTF printing to achieve high-quality results?

To achieve the best results in DTF printing, focus on using quality materials such as reliable films and inks, regularly calibrate your printer for accurate color representation, and ensure proper pre-treatment of fabrics. Additionally, mastering placement techniques and applying suitable post-production methods can significantly enhance the final output of your DTF prints.

What should I consider when designing for DTF printing?

When designing for DTF printing, use vector graphics for scalability and pay attention to color separations, as on-screen colors may differ from the final print. It’s essential to test your designs on actual fabric samples to adjust for material texture and stretch before full production.

How important is printer calibration in DTF printing?

Printer calibration is crucial in DTF printing as it ensures color accuracy and consistency, which are vital for producing stunning DTF designs. Regular adjustments according to the manufacturer’s guidelines help maintain optimal performance and minimize discrepancies between digital designs and printed results.

Can I incorporate special effects into my DTF prints?

Yes! Incorporating special effects such as metallic inks, glow-in-the-dark features, or textured finishes can elevate your DTF prints and make your designs stand out in a crowded market. Experimenting with these unique additions enriches visual appeal and enhances the overall quality of your prints.

What are some common issues and solutions in DTF printing?

Common issues in DTF printing include poor ink adhesion, color discrepancies, and design distortions on different fabrics. To address these, ensure proper pre-treatment of fabrics, maintain regular printer calibration, and validate design placements through test prints to identify and resolve potential complications before final production.

| Key Point | Description |

|---|---|

| Focus on Quality Materials | Invest in high-quality DTF films and inks for better prints. Brands like Inktec and Adkins are recommended. |

| Printer Calibration | Regular calibration ensures color accuracy and minimizes discrepancies in prints. |

| Design Considerations | Utilize vector graphics for scalability and test color separations to ensure print accuracy. |

| Pre-Treatment and Curing | Proper pre-treatment helps ink adhesion, while adequate curing maintains vibrancy and durability. |

| Understanding Pattern Placement | Adjust designs based on fabric type to ensure prints remain intact when worn. |

| Creativity with Special Effects | Incorporate techniques like metallic inks or textures to enhance visual appeal. |

| Keeping Up with Market Trends | Stay informed about trends to attract consumers with popular designs. |

| Mastering Post-Production | Use additional ink layers and textures to create depth and interest in your prints. |

Summary

DTF Printing Techniques are revolutionizing the way designs are printed, offering a dynamic method that surpasses traditional methods. By leveraging the full potential of DTF printing, one can achieve vibrant and high-quality fabric prints that not only catch the eye but also endure through time. The key lies in carefully selecting materials, mastering the printing process, and employing innovative design strategies. Understanding the nuances of quality inks, proper printer calibration, and meticulous attention to patterns can lead to outstanding results. Moreover, incorporating trending designs and creative effects can significantly enhance the appeal of your prints, making them stand out in a crowded market. Ultimately, embracing these DTF printing techniques can elevate your creations and establish a strong connection with customers seeking uniqueness and durability in their printed apparel.