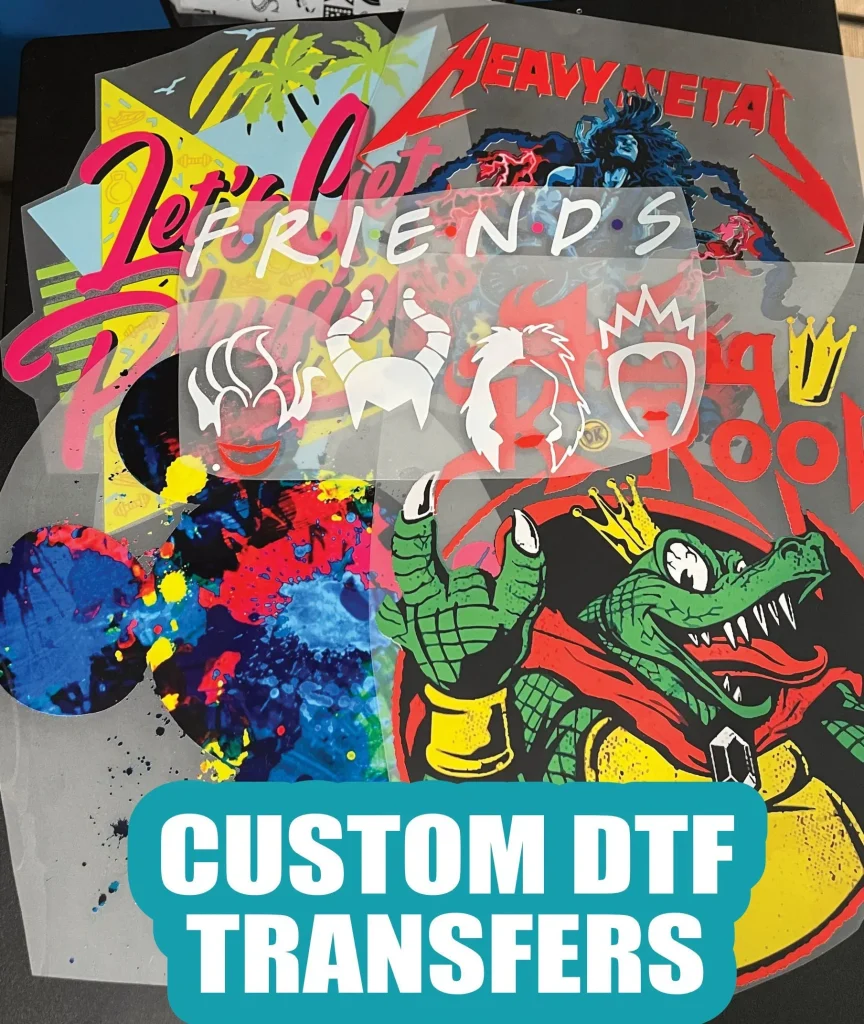

DTF transfers, or Direct-to-Film transfers, are rapidly gaining popularity in the custom apparel market, providing a modern alternative to traditional screen printing methods. This innovative approach allows for the transfer of high-resolution, vibrant designs onto various fabric types, making it a versatile choice for businesses and artists alike. One of the key benefits of DTF printing is its efficiency, enabling quicker turnaround times without sacrificing print quality. Furthermore, DTF transfers are more sustainable than screen printing, as they require significantly less water and produce minimal chemical waste. By understanding the advantages of DTF transfers, businesses can make informed decisions about their custom apparel printing needs, leading to satisfied customers and an eco-friendlier production process.

When it comes to modern printing techniques for custom garments, Direct-to-Film transfers represent a transformative shift in the industry. As companies look for more efficient and environmentally-responsible methods, DTF emerges as a compelling choice that meets high-quality expectations while providing a range of practical advantages. Similar to other custom printing methods, DTF allows for colorful, detailed designs to be applied to textiles, but with enhanced flexibility and lower costs. Additionally, this contemporary technique contrasts sharply with traditional screen printing, especially in terms of production speed and setup requirements. In exploring these alternative printing options, it becomes clear that DTF transfers are not just another trend, but a proactive step towards a more sustainable and efficient future in apparel printing.

The Superiority of DTF Transfers in Color Quality

DTF transfers are known for their exceptional ability to reproduce vibrant and intricate colors that simply outshine traditional screen printing techniques. The advanced technology employed in DTF printing allows for a full spectrum of colors to be applied with precision, ensuring that every detail in the design is captured perfectly. In contrast, screen printing, which involves layering inks onto a substrate, can lead to less vivid designs and muddled colors, especially when dealing with complex images or gradients. Therefore, businesses seeking to offer eye-catching, high-quality apparel will benefit significantly from choosing DTF over screen printing.

Additionally, DTF transfers boast remarkable consistency in color across various prints, which is crucial for branding and promotional items. This is particularly important for businesses that require large quantities of the same design, as DTF reduces the risk of color discrepancies that can occur with traditional printing methods. This quality not only enhances the aesthetic appeal of custom apparel but also helps maintain the integrity of a brand’s visual identity.

DTF Transfers vs. Screen Printing: A Material Compatibility Showdown

When it comes to material versatility, DTF transfers take the lead as a highly adaptable printing method. Unlike screen printing, which is often limited to specific fabric types to achieve optimal results, DTF printing can effectively adhere to a wide range of materials, including cotton, polyester, and even blends. This capability allows businesses to create custom apparel tailored to different occasions and preferences, catering to a broader audience with diverse fabric needs.

The ability of DTF transfers to work well on various textiles makes it an attractive option for designers looking to experiment with different products. Whether it’s for t-shirts, hoodies, or even accessories, DTF opens the door for innovation in custom apparel printing. Consequently, businesses that prioritize creativity and customization will find that DTF transfers not only meet but exceed their expectations for material versatility.

Understanding Setup Cost Advantages of DTF Transfers

One of the most appealing aspects of DTF transfers is their significantly lower setup costs when compared to screen printing. Screen printing requires intricate setup processes, including creating individual screens for each color in a design, which can be both time-consuming and costly. For small batches or custom projects, the cost involved in setting up multiple screens can be prohibitive, making screen printing less feasible for many businesses.

Conversely, DTF printing simplifies this process by allowing multiple colors to be printed in one go, thereby reducing setup time and costs. This efficiency not only saves money but also enables businesses to produce custom designs at a fraction of the traditional costs, making DTF a truly cost-effective solution for those looking to expand their custom apparel offerings.

The Advantage of Rapid Production Times with DTF Technologies

In an increasingly competitive market, the speed of order fulfillment can determine the success of a business. DTF printing excels in providing quick production times, allowing businesses to turn around orders faster than ever before. The streamlined process of DTF printing minimizes the extensive drying and setup times associated with screen printing, enabling quicker fulfillment of both urgent orders and regular demand.

This rapid production capability not only aids in customer satisfaction but can also enhance a company’s reputation for reliability. By adopting DTF transfers, businesses can meet last-minute demands without compromising quality, making this printing method an invaluable asset for companies aiming to thrive under pressure.

Environmental Responsibility in the Printing Industry: DTF’s Advantages

Sustainability has become an essential consideration in the printing industry, with consumers increasingly favoring eco-friendly practices. DTF printing presents a more sustainable choice compared to traditional screen printing, which often involves high water usage and the use of harsh chemicals for cleaning screens. DTF technology reduces water consumption significantly and generates less waste, marking it as a responsible option for businesses looking to lessen their environmental footprint.

Choosing DTF transfers can enhance a company’s image as a sustainable brand. In today’s market, where consumers are more conscious of their purchasing decisions, being associated with eco-friendly printing methods can appeal to a demographic that values corporate responsibility. By leveraging DTF’s environmental benefits, businesses not only contribute to a healthier planet but also attract customers who prioritize sustainability in their buying choices.

Ensuring Longevity: Durability of DTF Transfers

When choosing a printing method for apparel, durability should be a top consideration. DTF transfers are recognized for their impressive durability and wash resistance, allowing designs to maintain their vibrant appearance even after multiple laundry cycles. This reliability is essential for businesses that want to deliver quality products to their customers without the worry of designs fading or cracking.

In contrast, some methods of screen printing can struggle with longevity, particularly with designs that utilize multiple colors or intricate details that may fade over time. By opting for DTF transfers, businesses can assure their customers of the long-lasting quality of the apparel, reinforcing brand loyalty and customer satisfaction through superior product performance.

Frequently Asked Questions

What are the main benefits of DTF transfers compared to screen printing?

DTF transfers offer several advantages over screen printing, including vibrant color reproduction, versatility with various fabric types, lower setup costs, quicker turnaround times, and a more sustainable printing process. These features make DTF a preferred choice for custom apparel printing.

How do DTF transfers compare in quality to screen printing?

DTF transfers produce high-resolution and detailed designs, showcasing vibrant colors that maintain their appearance even after multiple washes. In contrast, screen printing can sometimes result in muddied colors due to ink layering, making DTF a superior option for quality.

Can DTF transfers be used on different fabric types?

Yes, one of the standout features of DTF transfers is their material versatility. They can be applied to a wide range of fabrics, including cotton, polyester, and blends, unlike screen printing which often requires specific fabrics for optimal results.

Are DTF transfers more cost-effective than screen printing?

DTF transfers generally have lower setup costs than screen printing, which needs individual screens for each color. This makes DTF a better choice for smaller orders or personalized items, ultimately saving time and money for businesses.

What is the environmental impact of using DTF transfers as a printing method?

DTF printing is considered more environmentally friendly than traditional screen printing because it uses significantly less water and produces less chemical waste. By opting for DTF transfers, businesses can demonstrate their commitment to sustainable printing practices.

How durable are DTF transfers compared to screen printed designs?

DTF transfers are known for their exceptional durability. They exhibit strong adhesion and withstand multiple washes without fading or cracking, making them a reliable option compared to some screen printing methods that may deteriorate over time.

| Key Advantages of DTF Transfers | |

|---|---|

| 1. Quality and Color Vibrancy | Produces high-resolution, vibrant designs that stand out, avoiding muddied colors common in screen printing. |

| 2. Material Versatility | Can be applied to various fabrics, unlike screen printing, which is limited to specific materials. |

| 3. Lower Setup Costs | Requires less setup than screen printing, making it ideal for small orders and reducing overall costs. |

| 4. Quick Turnaround | Offers faster production times, which is crucial for meeting urgent customer demands. |

| 5. Environmental Impact | More eco-friendly than screen printing, with less water usage and chemical waste. |

| 6. Durability and Wash Resistance | Maintains quality after multiple washes, unlike some screen printing methods. |

Summary

DTF transfers represent an innovative solution in the realm of custom printing, offering impressive advantages that set them apart from traditional screen printing methods. With remarkable qualities such as vibrant color accuracy, versatility across diverse materials, and lower costs for setup and production, DTF transfers are ideal for businesses looking for efficiency and quality. The quick turnaround times facilitate responsive service to customers while the heightened durability ensures long-lasting designs that withstand multiple washes. Moreover, DTF transfers are environmentally friendly, making them a responsible choice for modern businesses keen on sustainability. As the custom apparel industry continues to adapt, incorporating DTF transfers can lead to enhanced creativity and customer satisfaction, positioning companies for success in an increasingly competitive market.