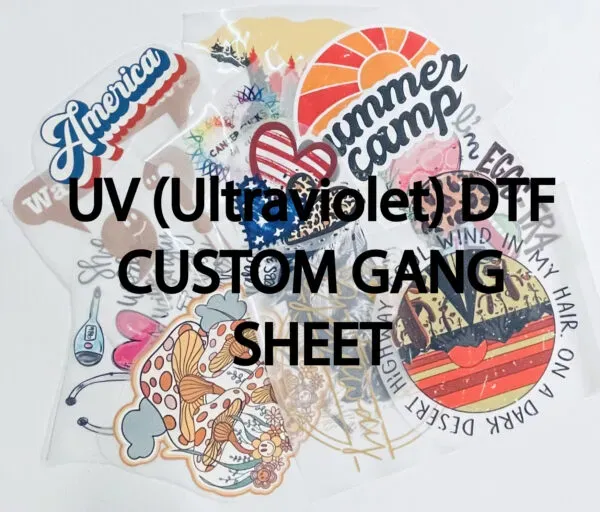

UV DTF Gangheet is revolutionizing the world of graphic design printing, combining both efficiency and quality with the capabilities of UV printing techniques. This cutting-edge method allows designers to transfer vibrant graphics onto a variety of materials, from textiles to plastics, with remarkable precision and durability. As an innovative form of direct-to-film printing, UV DTF Gangheet offers a quick-drying solution that significantly enhances production speeds, making it the go-to choice for professionals in the industry. By utilizing specially formulated UV inks that cure instantly under ultraviolet light, this technique ensures that the resulting UV prints are not only visually striking but also long-lasting. With the right knowledge and material selection, anyone can master this technology and elevate their textile printing projects.

Exploring the dynamics of UV DTF printing, often referred to as direct-to-film transfer methods, provides exciting insights into advanced graphic design capabilities. This technique has seen a surge in popularity due to its ability to create high-definition prints on a variety of substrates, enhancing creativity in textile applications. Users often leverage its advantages to produce intricate designs with excellent adherence and bold colors, making it a significant advancement in printing technology. Understanding the nuances behind this innovative approach not only empowers designers to create unique products but also optimizes their workflow through efficient ink and curing processes. For those looking to gain an edge in textile printing, these modern methods of direct printing promise to transform their creative outputs.

Exploring the Advantages of UV DTF Printing

UV DTF printing, or Direct-to-Film printing, stands out as a revolutionary technology in the world of graphic design printing. One of its most significant advantages is the ability to produce vibrant, sharp images across various materials, from textiles to plastics. The key lies in the use of UV inks that dry quickly under ultraviolet light, allowing for reduced processing time and enhanced production efficiency. This capability not only caters to a diverse range of substrates but also ensures high-quality prints suitable for both personal and commercial uses.

Furthermore, UV DTF printing opens up a world of possibilities for artistic expression and design creativity. By catering to different materials like wood and metal, designers can explore unconventional surfaces that traditional printing methods may not support. This flexibility empowers graphic designers to think outside the box, create custom promotional items, or produce unique textile designs, thus setting their work apart in a highly competitive market.

Essential Material Selection for UV DTF Printing

Choosing the right materials is fundamental to achieving impressive results in UV DTF gangheet. High-quality substrates can significantly affect adhesion and print longevity. For instance, soft and lightweight textiles are excellent choices for apparel, providing vibrant colors that enhance the garment’s appeal. Similarly, rigid surfaces such as plastics and wood offer outstanding engagement for signage and promotional merchandise, allowing, in some cases, even for intricate designs that demand precision.

Additionally, the release liner used in conjunction with UV DTF films plays a crucial role in the printing process. A superior quality release liner ensures that the prints adhere properly and remain vibrant over time. Whether you are experimenting with a trendy new plastic or selecting the perfect textile for your next project, ensuring that the materials used meet high standards will drastically enhance the quality of your final prints.

Setting Up Your UV DTF Printer Correctly

A successful UV DTF printing venture starts with the correct setup and calibration of your printer. Print head alignment is vital to ensure each print is uniform and accurately reflects the intended design. Additionally, configuring appropriate color profiles based on the substrate type will create harmony between the printed output and the actual colors you aim to achieve, thereby eliminating common production discrepancies.

Thermal and humidity conditions are also integral in the UV DTF printing setup. An optimal environment that balances these factors will help to prevent issues such as ink inconsistency and curing problems during production. By paying close attention to these calibration tips, you can create a stable printing environment that leads to more successful and visually appealing prints.

Optimizing Ink Management for Optimal Results

In UV DTF printing, the quality of inks used can significantly influence the integrity of your prints. Utilizing specially formulated UV inks that are compatible with both the film and substrates is essential. It ensures vibrant colors and solid adhesion to the materials, resulting in prints that are not only visually striking but also durable. For example, if the ink is mismatched with the materials, it could lead to subpar print qualities and failure in production.

Moreover, regular maintenance of ink lines and systems is vital. Cleaning and inspecting these systems frequently helps to prevent clogs and ensures that the inks flow smoothly during the printing process. Establishing a routine maintenance schedule will not only preserve the printer’s functionality but also enhance your overall print quality, allowing for consistently excellent results.

Mastering the Curing Process for Lasting Prints

The curing process is one of the most crucial steps in UV DTF printing, directly impacting the quality and durability of the final product. Proper curing involves experimenting with different times and distances from the UV light source to determine the optimal settings for your specific materials and designs. This stage is integral, as under-curing can lead to smudges and fading, while over-curing may create a brittle finish that detracts from the print’s quality and longevity.

Achieving the perfect curing balance ensures that the prints maintain their vibrancy and withstand everyday wear and tear. Thus, investing time in the curing stage not only enhances the visual appeal of your prints but significantly extends the life of your products, making this process essential for successful UV DTF gangheet.

Creative Application Techniques in UV DTF Printing

When applying UV DTF prints, employing creative techniques can elevate the quality and uniqueness of your work. Layering different colors of inks can add depth and dimension, making the designs stand out. This approach invites a tactile experience, as observers can appreciate the richness that multiple ink layers provide. Similarly, experimenting with ink mixing can yield exciting outcomes that lead to custom designs not found in traditional printing methods.

Additionally, incorporating other methods like sublimation alongside UV DTF could lead to even higher quality results. Blending techniques opens avenues for artists and designers to create innovative prints that push the boundaries of conventional design and production, establishing a unique pitch in the crowded market of textile printing.

Frequently Asked Questions

What is UV DTF Gangheet and how does it differ from traditional printing techniques?

UV DTF Gangheet, or Direct-to-Film printing, utilizes UV inks cured by ultraviolet light, unlike traditional printing methods that often rely on solvent inks and drying processes. This technology allows for quicker drying times and improved print adhesion on various substrates, making it ideal for graphic design printing.

What materials are best for UV DTF Gangheet printing?

For UV DTF Gangheet printing, optimal materials include lightweight textiles, plastics, and wood. Each substrate requires careful selection to achieve the best print quality, ensuring that the release liner used is of high quality for effective adhesion.

How important is printer setup for successful UV DTF Gangheet?

Printer setup is crucial for UV DTF Gangheet success. Proper calibration, including print head alignment and updating color profiles for different substrates, ensures consistent color output and overall quality in your prints.

What are some tips for curing UV DTF prints effectively?

Effective curing in UV DTF printing is essential for durability. Experiment with curing times and distances to find the optimal settings, as proper curing prevents issues like smudging from under-curing and brittleness from over-curing.

Can UV DTF Gangheet be combined with other printing techniques?

Yes, UV DTF Gangheet can be creatively combined with other techniques like sublimation. This integration can enhance the quality and versatility of the final prints, allowing designers to explore unique effects and custom designs.

How can I maintain the longevity of my UV DTF prints?

To ensure the longevity of your UV DTF prints, apply protective coatings on final products, store them in cool, dry places, and handle them with clean hands to avoid smudges. Regular maintenance of your printer and inks is also critical to prevent clogs and ensure print quality.

| Key Point | Description |

|---|---|

| UV DTF Technology | An innovative printing method gaining popularity in textile and graphic design, enabling printing on various materials with quick drying and high quality. |

| Material Selection | Choosing the right substrates, such as textiles, plastics, and wood, is critical. High-quality release liners enhance adhesion and print vibrancy. |

| Printer Setup | Regular calibration, print head alignment, and environmental control ensure consistent quality and color output in UV DTF printing. |

| Ink Management | Using high-quality UV inks and ensuring compatibility with substrates is vital for optimal print results. |

| Curing Process | Proper curing time and distance are crucial to achieving durable, vibrant prints without smudging or brittleness. |

| Application Techniques | Techniques like layering and ink mixing can enhance print quality and create unique designs. |

| Final Touches | Applying protective coatings and proper storage methods prolong the life and quality of prints after production. |

| Recent Developments | Although limited resources exist, keeping updated through professional magazines and workshops can enhance UV DTF Gangheet proficiency. |

Summary

UV DTF Gangheet ensures quality and innovation in modern printing practices. This comprehensive guide provides essential insights into mastering techniques and best practices that drive success in UV DTF printing. By understanding the intricacies of technology selection, material preparation, printer setup, and curing processes, professionals can achieve high-quality results. As UV DTF continues to evolve, staying informed through industry resources and community engagement will empower practitioners to elevate their craft to new heights.