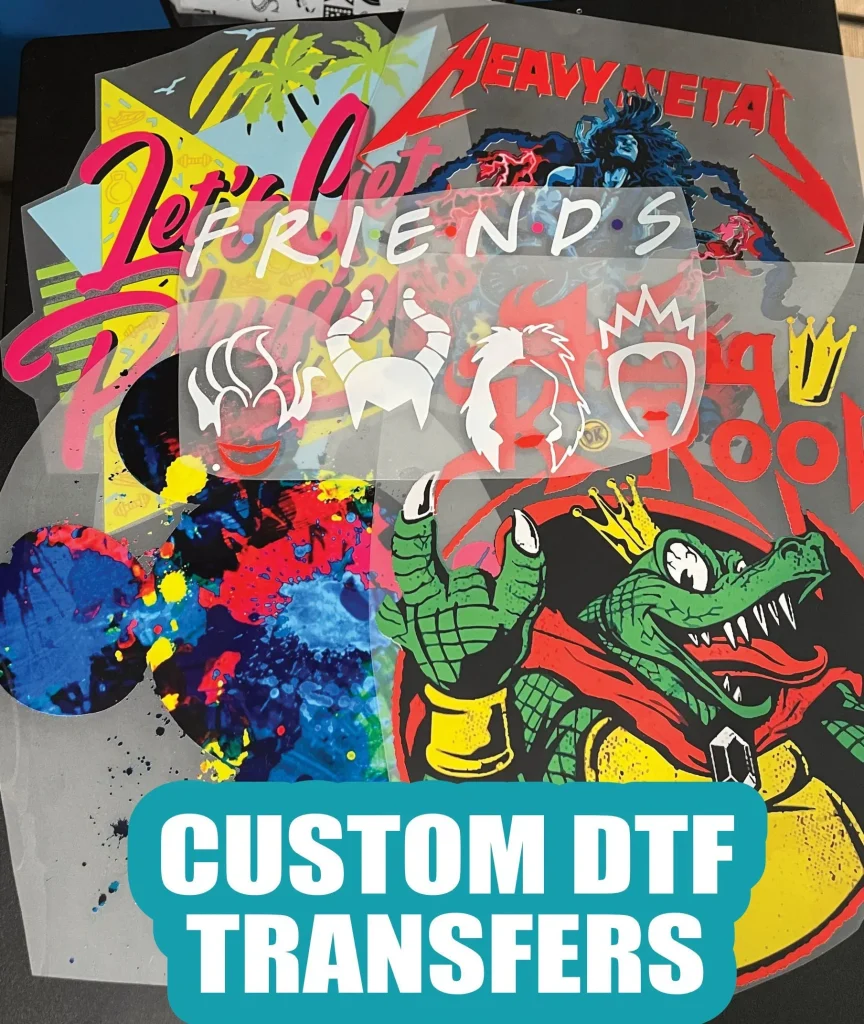

DTF transfers, or Direct to Film transfers, are revolutionizing the world of textile printing and dispelling many myths in the process. As this innovative printing technology gains traction, it’s essential to clarify what DTF transfers are truly capable of. One of the most appealing aspects of DTF printing lies in its versatility—allowing for vibrant, high-quality designs on a variety of fabrics, from cotton to polyester. Many skeptics dismiss DTF as a costly and fleeting trend, yet the reality is that it offers numerous benefits including longevity, durability, and ease of use compared to other printing methods. Understanding these advantages will empower you to make informed choices about why you should choose DTF for your printing needs, ensuring you stand out in a competitive market.

In recent years, direct-to-film printing has emerged as a captivating alternative in the realm of fabric decoration. This method allows creators to transfer stunning designs onto garments with ease, providing flexibility that traditional printing techniques often lack. The popularity of heat transfers and inkjet technology has paved the way for this modern approach, which is now favored by many for its efficiency and reliability. As you explore the possibilities of transfer printing, consider the compelling benefits DTF offers, including its ability to produce vibrant colors on both light and dark surfaces. By embracing these advanced printing solutions, you can unlock new levels of creativity in your textile projects.

Understanding the Cost-Effectiveness of DTF Transfers

When evaluating the cost of DTF transfers, it’s essential to understand the long-term savings they can provide. Initially, the setup may seem expensive; however, DTF printing technology is designed to be a worthy investment. Compared to traditional methods, DTF offers superior quality while significantly reducing costs associated with frequent reprints. The longevity of DTF prints means that businesses can save money over time, as the need for replacements diminishes. Additionally, the ease of use of DTF transfers reduces labor costs, making it an economically sound choice for companies aiming to maximize profits.

Many businesses that adopt DTF printing observe a rapid return on their investment due to the growing demand for high-quality prints in various sectors, including fashion and custom merchandise. By focusing on the durability and vibrancy of DTF prints, companies can justify the up-front costs in favor of the reliable output over time. Therefore, shifting the perception that DTF transfers are prohibitively expensive allows potential users to explore its economic advantages, contrary to popular belief.

The Versatility of DTF Printing Options

DTF printing is widely recognized for its adaptability across a multitude of fabrics, breaking the myth that it’s limited to cotton alone. This technology allows users to create designs on polyester, blends, and more specialized materials, catering to various industries from sportswear to promotional items. The capability to print on both dark and light fabrics extends creative possibilities, making DTF a preferred choice for designers and businesses alike. As a result, the versatility of DTF transfers caters to diverse markets, ensuring that customers find the right solutions for their specific needs.

In addition to fabric variety, DTF’s ability to reproduce intricate designs with precision is a notable benefit. This makes it ideal for producing custom graphics, logos, and detailed artwork. Such versatility not only enhances the aesthetic quality of clothing and merchandise but also allows businesses to offer unique products that stand out in a competitive landscape. Consequently, recognizing the wide range of applications for DTF transfers promotes its use beyond traditional boundaries.

Debunking the Durability Myths Around DTF Prints

One prominent myth surrounding DTF printing is the idea that these prints fade quickly after a few washes. However, the reality is quite the opposite. DTF prints, when applied with high-quality inks and followed by proper curing techniques, exhibit remarkable durability. Studies have shown that prints can withstand numerous washes without showing significant signs of wear. This longevity ensures that items printed using DTF technology remain vibrant for extended periods, making it an ideal choice for brands focusing on quality and retention.

To further dispel this misconception, it’s essential to consider the advancements in DTF materials and techniques. With continuous improvements in ink formulations and application processes, the fade resistance of DTF prints has dramatically increased. Customers can expect their designs to remain bright and intact, even under commercial laundry conditions. By understanding the true longevity of DTF transfers, businesses can confidently use this method for their printing needs without the fear of rapid deterioration.

Simplifying DTF Equipment and Setup Requirements

A frequent misunderstanding about DTF printing is the complexity of its equipment. However, modern DTF printers are designed with user-friendly interfaces that cater to beginners. Unlike traditional methods that may require extensive training, many DTF systems come equipped with straightforward instructions and support resources, making the transition to this printing method seamless. Users can easily navigate the basics of setup, ensuring that they can start producing prints quickly and efficiently.

Moreover, as technology advances, DTF printers are becoming more affordable and accessible to smaller businesses and individual creators. The rise of comprehensive online tutorials and community support adds an extra layer of convenience, equipping new users with the knowledge to operate these systems competently. This accessibility reduces the intimidation factor associated with adopting a new printing technology, thereby encouraging wider use of DTF printing.

Why Choose DTF Over Other Printing Methods

When considering which printing method to use, many individuals and businesses are faced with a plethora of options. DTF printing stands out among them due to its unique advantages, including vibrant color reproduction and flexibility across multiple fabric types. Other methods, such as screen printing, often lack the precision and adaptability offered by DTF, especially in terms of small batch customization without incurring high costs. This distinct edge makes DTF an attractive option for brands looking to differentiate themselves from competitors.

Additionally, DTF printing provides seamless integration into existing workflows, making it an optimal choice for businesses aiming for efficiency. The ability to handle elaborate designs with ease and without considerable setup times distinguishes DTF from alternatives like Direct to Garment (DTG) or traditional screen printing. As companies seek effective solutions that fit their budget and operational capabilities, DTF transfers repeatedly prove to be a frontrunner in the ever-evolving landscape of textile printing.

The Future of DTF Printing in the Textile Industry

Despite skepticism regarding its staying power, DTF printing is increasingly recognized as a transformative technology within the textile industry. As demand for high-quality, customizable solutions grows, DTF’s capacity to deliver durable, vibrant prints positions it well for the future. Companies that bet on DTF printing not only benefit from its current advantages but also from its potential for further innovation as the technology evolves.

With continuous development in printing technology, DTF is expected to adapt and thrive, keeping pace with emerging market needs. Increased sustainability efforts and the push towards eco-friendly materials further bolster DTF’s credibility as a long-term solution in the printing industry. By embracing DTF now, businesses are not just meeting today’s demands but are also preparing for the future landscape of textile printing, ensuring they remain competitive and relevant.

Frequently Asked Questions

What are some common DTF printing myths?

Many myths surround DTF transfers, including the ideas that they are too expensive, only suitable for cotton, or that prints fade quickly. In reality, DTF technology is versatile, cost-effective long-term, and produces durable prints across various fabrics.

What are the benefits of choosing DTF transfers over other printing methods?

DTF transfers offer several benefits, such as the ability to print on multiple fabric types, vibrant colors that last, and a user-friendly setup for beginners. These advantages make DTF a compelling option compared to traditional methods like screen printing or heat transfer.

Is DTF printing only for cotton fabrics?

No, DTF transfers can be applied to a wide range of materials, including polyester, blends, and specialty fabrics. This versatility makes DTF suitable for various applications, extending beyond just cotton.

How do DTF transfers compare to other printing methods in terms of durability?

DTF prints are known for their remarkable durability and resistance to fading, which often surpasses that of many other printing methods. When quality inks and proper application techniques are used, DTF prints can withstand multiple washes while maintaining their vibrancy.

Why should I choose DTF printing for my business?

Choosing DTF printing offers unique advantages such as cost-effectiveness, versatility in fabric types, and high-quality prints. Its growing popularity and sustainable practices also make DTF an appealing option for businesses looking to innovate in the textile market.

What equipment do I need for DTF transfers, and is it complicated to set up?

To start with DTF transfers, you need a DTF printer and a heat press. However, many modern DTF printers are designed to be user-friendly, making setup accessible for beginners. With available online tutorials and resources, learning the process becomes easier.

| Myth | Fact |

|---|---|

| DTF Transfers Are Expensive | DTF transfers can be cost-effective in the long run due to their durability and quality, minimizing reprints. |

| DTF Printing is Only for Cotton Fabrics | DTF technology is versatile and works well on cotton, polyester, blends, and specialty fabrics. |

| DTF Prints Fade Quickly | DTF prints can last for many washes without fading when applied with quality inks and techniques. |

| DTF Transfers Require Complicated Equipment | Modern DTF printers are user-friendly and accessible, even for beginners. |

| DTF is Just Another Fad | DTF is a growing trend with significant technological advancements and increasing industry acceptance. |

Summary

DTF transfers offer a variety of benefits that illuminate common misconceptions. From their long-term cost-effectiveness to the wide range of compatible fabrics, the advantages of DTF printing are impressive. The durability of prints combined with user-friendly technology underscores that DTF is a significant investment in contemporary printing. By understanding the realities underlying these myths, we can truly value the potential of this innovative method. As the interest in DTF transfers increases, so too will the emergence of more developments and educational resources, ensuring its prominence in the textile printing sector.