DTF transfers, or Direct to Film transfers, are revolutionizing the custom apparel printing industry by offering an innovative method for applying vibrant designs to fabrics. This cutting-edge printing technique combines the advantages of traditional heat transfer methods with the precision and quality of modern printing tools. With DTF printing, users can achieve full-color designs without the hassle of multiple screens or setups, making it a preferred choice for many creators aiming for professional results. In this guide, we will delve into the essential tools and techniques necessary for successful DTF transfers, exploring how this method unlocks creative possibilities while ensuring durability and color vibrancy. Get ready to transform your apparel printing game with this exciting advancement in heat transfer techniques!

When exploring the world of garment decoration, one may encounter a variety of terms, including Direct to Film transfers, film printing, or simply DTF methods. This approach to custom printing utilizes specialized technology to bring designs to life on different fabrics effectively. Using advanced printing methods, creators can achieve high-quality, durable prints with rich colors that are sure to impress. By employing careful techniques and the right tools, the transition to using these innovative heat transfer methods can be seamless and rewarding. Let’s dive deeper into what sets this technique apart and how it can enhance your custom apparel projects!

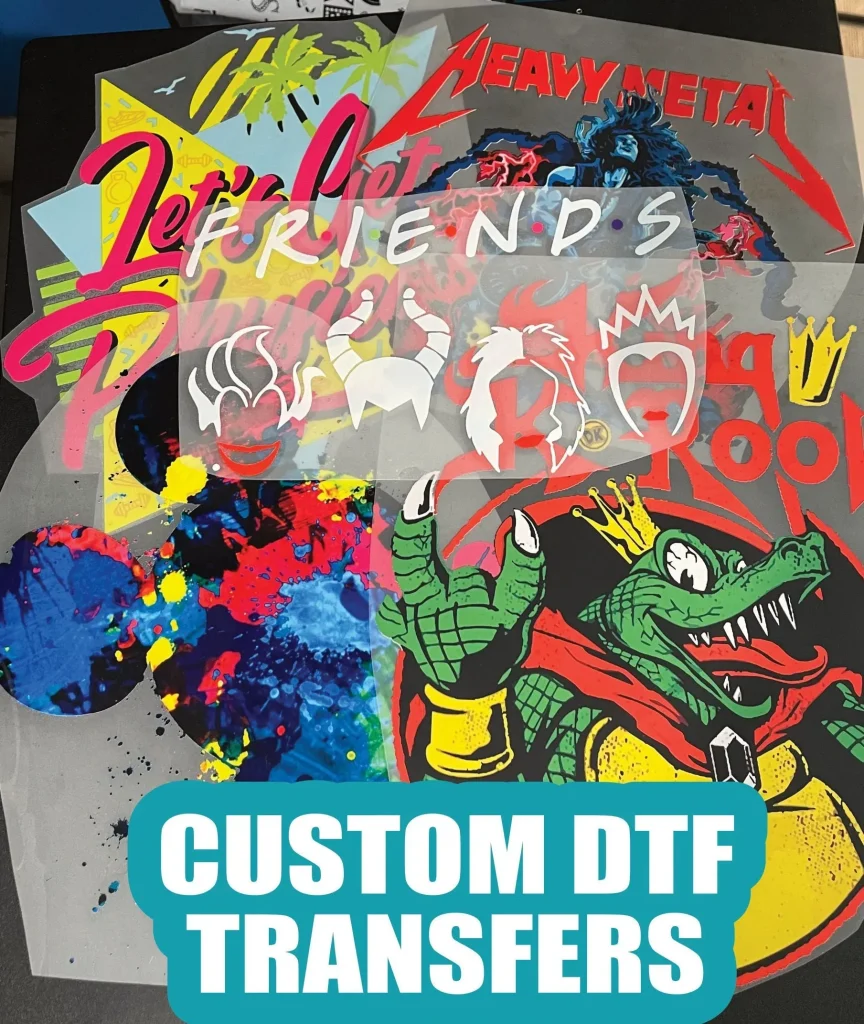

Understanding DTF Transfers: A Revolutionary Technique

Direct to Film (DTF) transfers represent a significant advancement in the custom printing industry. This innovative method simplifies the process of transferring high-quality images onto a variety of fabrics. The DTF printing process effectively caters to the needs of creators who demand vibrant color outputs and ease of use. With the ability to print intricate designs with fully saturated colors, DTF transfers eliminate the hassle often associated with traditional printing methods such as screen printing. As businesses and artists continue to embrace this technique, it becomes vital to understand its nuances and applications.

Moreover, the market for custom apparel has been evolving, and DTF transfers provide a solution that meets modern demands. They enable printing on diverse materials, such as cotton, polyester, and blends, expanding the range of products that can be personalized or branded. The ease of use and versatility of DTF transfers make them the preferred choice for many designers and companies aiming to deliver quality merchandise.

Essential Tools for DTF Printing Success

Investing in the right tools is crucial for anyone looking to get started with DTF transfers. First and foremost is the DTF printer, which uses specialized water-based inks designed for vibrant color reproduction on transfer film. Unlike ordinary printers, DTF printers are tailored to handle various substrates, offering the reliability and quality necessary for professional-grade outputs. Without the right printer, achieving the detailed and colorful designs that make DTF transfers appealing can be challenging.

In addition to the DTF printer, a quality heat press is essential. This tool not only applies the needed heat but also ensures that pressure is uniformly distributed across the printed film as it adheres to the substrate. Using a heat press designed specifically for DTF transfers can enhance the durability and clarity of the print, ultimately impacting customer satisfaction. Investing in high-quality adhesive powders and films further complements these tools, adding to the final product’s longevity.

Mastering the DTF Printing Process

The DTF printing process involves several key steps that, when mastered, yield stunning results. Preparation is fundamental; high-resolution designs should be created and saved in a mirrored format before printing to ensure they appear correctly on the final product. The quality of prints heavily relies on the accuracy of color settings and the characteristics of the transfer film. Before diving into full production, conducting test prints can help identify any potential challenges, allowing for adjustments before scaling up.

Once the design is printed onto the DTF film, it is vital to apply the adhesive powder promptly while the ink is still wet. This ensures that the powder bonds effectively and sets the stage for a successful transfer. Following this, the application of heat through the heat press must align with fabric-specific guidelines to achieve the best adhesion. Mastering these processes not only leads to impressive outputs but also enhances operational efficiency, making your custom printing endeavors more fruitful.

Post-Production Tips for DTF Transfers

After applying a DTF transfer, proper post-production practices can make a significant difference in the longevity and visual appeal of the product. Once the fabric has cooled following the heat press, it’s essential to check the adherence of the design thoroughly. Any signs of lifting or poor adhesion may indicate that adjustments are necessary in the future, such as experimenting with temperature, pressure, or time settings during the application process.

Furthermore, adhering to proper washing and care instructions after transfers can help ensure that the vibrant colors and integrity of the design remain intact over time. Customers appreciate instructions on how to maintain the quality of their apparel, and offering this information can enhance their experience and build trust in your brand. Over time, good practices in post-production will reflect positively on your reputation as a quality custom apparel printer.

The Advantages of Using DTF Transfers for Custom Apparel

DTF transfers come with a multitude of benefits that differentiate them from traditional printing techniques. One of the standout advantages is the sheer versatility of this method; DTF transfers can be applied to a wide range of fabrics, including tricky materials such as polyester and blends, which can be challenging for other methods like screen printing. This flexibility enables businesses to cater to various customer needs, expanding the range of products available for customization.

Another key benefit is the durability of the prints created using DTF transfers. They are designed to withstand multiple washes, ensuring that they maintain their vibrant appearance even after repeated use. This resistance to fading, cracking, and peeling adds significant value to the products, making DTF transfers a preferred choice for high-demand items such as sportswear and promotional apparel.

Exploring Future Trends in DTF Printing

As technology advances, the landscape of custom printing is continually evolving. DTF printing is at the forefront of this transition, with trends moving towards greater efficiency and automation. The development of faster, more precise DTF printers is making it increasingly feasible for businesses of all sizes to produce high-quality prints quickly, elevating their competitive edge in the custom apparel market.

Additionally, there’s a growing emphasis on sustainable printing practices. Eco-friendly inks and materials are being developed to minimize environmental impact, catering to a conscientious consumer base that values sustainability. This shift not only aligns with contemporary market demands but also presents an opportunity for custom printers to differentiate themselves by spotlighting their commitment to eco-friendly practices within the vibrant world of DTF printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that is then transferred onto fabric using heat and pressure. This innovative technique allows for vibrant, durable designs that can be applied to various fabrics, making it a popular choice in custom apparel printing.

What tools do I need for DTF printing?

To get started with DTF printing, you’ll need essential tools such as a DTF printer for high-quality ink prints, a heat press to transfer designs, DTF transfer film for applying images, adhesive powder to bond ink to fabric, and optionally a curing oven for uniform results during production.

How do I prepare designs for DTF transfers?

Preparing designs for DTF transfers involves using graphic design software to create high-resolution images. Ensure to optimize colors for DTF printing and remember to mirror the design before printing so that it appears correctly on the fabric after transfer.

What makes DTF transfers more versatile than traditional printing methods?

DTF transfers are highly versatile because they can be applied to a wide range of fabrics, including cotton, polyester, and blends. This flexibility allows custom apparel printing on various items, from T-shirts to promotional gear, without needing multiple setups for different materials.

Why are DTF prints known for their durability?

DTF prints are recognized for their durability due to the high-quality inks and adhesive powder used in the process. These elements help the prints resist wear and tear, retain vibrancy after multiple washes, and prevent cracking, making them ideal for high-use clothing items.

What are the key factors for successful DTF transfer application?

Successful DTF transfer application relies on critical factors such as proper design preparation, accurate printing on DTF film, timely adhesive powder application, adhering to recommended heat press settings for temperature and pressure, and ensuring a thorough post-transfer check before using the item.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | DTF transfers involve printing designs onto special film and transferring them to fabric using heat and pressure. |

| Essential Tools | Key tools include a DTF printer, heat press, DTF transfer film, adhesive powder, and optionally a curing oven. |

| Techniques for Success | Essential techniques include design preparation, printing, powder application, transfer application, and post-transfer cleanup. |

| Benefits of DTF Transfers | DTF transfers are versatile, durable, and produce vibrant colors ideal for various fabrics. |

Summary

DTF transfers have emerged as a revolutionary printing method that brings together efficiency and extraordinary design vibrancy. By understanding the essential tools and techniques required for DTF transfers, anyone can create stunning and durable prints suitable for a wide array of fabrics. The combination of high-quality DTF printers, specialized materials, and the proper application techniques ensures that designs not only look great but also stand the test of time, making DTF transfers a valuable asset for custom apparel decoration. Whether for personal projects or commercial endeavors, embracing this innovative method opens up a world of creative potentials.