The DTF process, or Direct-to-Film printing, has revolutionized the world of textile design by offering a seamless and efficient way to transfer intricate images onto various fabrics. This innovative printing technique allows both beginners and seasoned professionals to achieve remarkable color vibrancy and fine detail, making it an appealing choice for custom apparel. In this guide, we’ll explore not only the fundamentals of the DTF printing process but also share tips on how to do DTF printing effectively. Understanding DTF transfer techniques can transform your creative ideas into stunning fashion statements. Whether you’re an artist looking to express your style or a small business owner wanting to elevate your product line, mastering the DTF process is your gateway to a new level of printing success.

Direct-to-Film printing, often abbreviated as DTF printing, represents a cutting-edge methodology that offers a new horizon for fabric decoration enthusiasts. This technique utilizes specialized transfer films that enhance the quality of printed designs while simplifying the transfer process to textiles. By learning how to navigate this modern printing landscape, individuals can create captivating designs that stand out in a crowded market. Additionally, various DTF transfer techniques enable users to experiment with their creativity, yielding a plethora of custom products. For those just starting, this beginner’s guide to DTF will help demystify the printing process and empower you to unleash your artistic potential.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a modern technique that bridges the gap between traditional printing methods and cutting-edge technology. This process stands out due to its ability to produce high-quality prints with vivid colors and intricate details. Unlike conventional approaches like screen printing, DTF printing employs a special film that enables a seamless transfer of complex designs onto various fabrics. This versatility makes it an ideal choice for everyone, from small business owners to DIY enthusiasts.

Moreover, the DTF printing process is notably user-friendly, which greatly appeals to beginners. With access to graphic design software such as Adobe Illustrator and basic printing equipment, anyone can start creating custom prints with relative ease. High resolutions and careful handling of materials ensure that the end results are nothing short of impressive, marking DTF printing as a suitable choice for those new to the field.

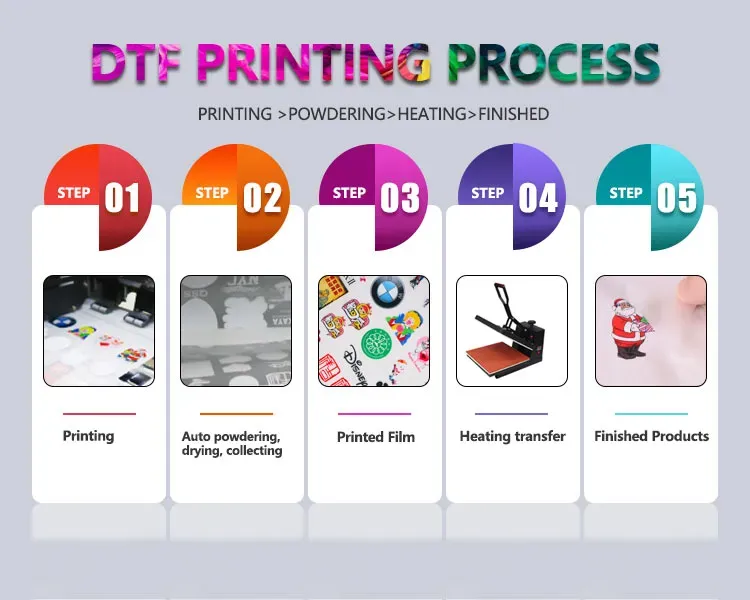

Step-by-Step Guide: How to Do DTF Printing

The DTF process starts with designing your artwork, which requires using software that allows for precise adjustments and creative output. A commonly used format is PNG due to its support for transparent backgrounds, crucial for ensuring that only the intended design is printed. Once your design is finalized, it’s time to transfer it onto the DTF transfer film using a DTF printer. This phase is vital since the print quality heavily depends on the resolution and color fidelity at this stage.

Follow this by applying a powder adhesive to the printed film, which plays an essential role in ensuring the design adheres to the fabric securely. The activation of this adhesive through curing, typically at temperatures around 320°F for 15-20 seconds, is a crucial step in the DTF printing process. This not only sets the adhesive but ensures that the print’s durability and vibrancy remain intact, allowing for high-quality final products.

Essential Tips for Effective DTF Transfer Techniques

To ensure a successful DTF printing experience, beginners should focus on a few essential practices. First, conducting test prints on scrap materials allows for adjustments to be made before the final application, preventing costly mistakes. Moreover, prioritizing high-quality materials such as DTF transfer films and specialized inks will significantly improve print quality and longevity, ensuring that your designs stand out.

Additionally, familiarity with the heat press settings appropriate for different fabrics can mitigate the risk of damage during the transfer process. Taking the time to research various DTF supplies and materials will also empower you to make informed choices that enhance the printing experience, ultimately leading to more satisfying and professional-looking results.

Recent Innovations in DTF Printing Technology

The field of DTF printing is rapidly evolving, with new innovations that enhance efficiency, quality, and accessibility for beginners and seasoned professionals alike. Suppliers are continually developing improved DTF films and inks that promise better adhesion and color vibrancy. These advancements broaden the appeal of DTF technology, allowing more individuals to embrace this exciting printing method in their projects.

Moreover, the democratization of DTF printing has led to the growth of vibrant online communities where enthusiasts and beginners can exchange ideas, resources, and support. Websites such as the Printful Blog or the T-Shirt Magazine serve as valuable platforms for tutorials, helping newcomers navigate the nuances of the DTF printing landscape effectively.

Common Challenges Faced by Beginners in DTF Printing

Every printing method comes with its set of challenges, and DTF printing is no exception. Beginners may struggle with settings on their heat press or find it difficult to achieve consistent print quality due to a lack of experience. Common issues include improper adhesive application, which can lead to peeling designs, and incorrect curing temperatures that can ruin prints.

To overcome these hurdles, it’s crucial for newcomers to seek guidance through online tutorials or community forums. Engaging with experienced printers can provide insights and troubleshooting tips, making the learning curve less steep. As with any skill, practice and persistence are invaluable, and the more you experiment with DTF printing, the more proficient you become.

The Future of DTF Printing in the Custom Apparel Market

As DTF printing continues to gain traction, it is poised to transform the custom apparel market significantly. The ability to produce vibrant, durable designs with comparatively lower costs than traditional printing methods makes DTF an attractive option for entrepreneurs. This shift may lead to increased competition and innovation within the industry, catering to the evolving demands of consumers seeking unique and customized apparel.

Furthermore, as the technology matures, businesses can expect developments that make DTF more accessible and efficient. New tools may emerge to streamline the design-to-print process, thereby empowering creators and enabling small businesses to thrive without hefty investments in traditional printing equipment.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves printing designs onto a special transfer film using a dedicated DTF printer. This process allows for high-quality, vibrant prints that are then transferred onto fabric using heat and adhesive powder. It is a favored technique for both professionals and beginners in fabric printing.

What materials do I need for the DTF process?

To successfully execute the DTF process, you will need a DTF printer, specialized DTF transfer film, DTF inks, powdered adhesive, and a heat press. These materials are crucial for achieving the best results in your fabric designs.

How can beginners start with DTF printing?

For beginners interested in DTF printing, it’s essential to start by familiarizing yourself with graphic design software for creating your designs. Next, acquire the necessary materials like a DTF printer and transfer film. Following a step-by-step guide to the DTF process will help streamline your learning and improve your outcomes.

What are the benefits of using DTF transfer techniques over traditional printing methods?

DTF transfer techniques offer several advantages over traditional printing methods such as screen printing. These benefits include the ability to print complex designs in vibrant colors, ease of use for beginners, and the capability to print on a variety of fabrics without the need for extensive setup.

What is the recommended temperature and time for curing DTF prints?

When curing DTF prints, the recommended temperature is typically around 320°F (160°C) for 15-20 seconds. However, it’s crucial to follow the specific instructions provided by your film and adhesive manufacturers to ensure optimal results and avoid damaging your print.

Can I use any fabric for DTF printing, or are there limitations?

While the DTF process is versatile and can be used on various fabrics, it is best suited for materials like cotton, cotton blends, polyester, and some synthetics. Avoid using fabrics with high stretch or texture as they may not yield the best results in DTF printing.

| Step | Description |

|---|---|

| 1. Design Creation | Create your design using graphic software; ensure high resolution (at least 300 DPI). |

| 2. Printing the Design | Print the design using a DTF printer on the transfer film with specialized inks. |

| 3. Applying Powder Adhesive | Apply powdered adhesive to the wet ink on the film for better adhesion during transfer. |

| 4. Curing the Adhesive | Cure the adhesive using a heat press or oven to activate it at around 320°F for 15-20 seconds. |

| 5. Transferring the Design | Press the film onto the garment using a heat press while ensuring the correct settings. |

| 6. Peeling Off the Film | Allow the design to cool before carefully peeling off the transfer film to reveal the design. |

| 7. Curing the Transfer | Press again to finalize the design, ensuring durability through washes. |

Summary

The DTF Process is an innovative and efficient method for transferring designs onto fabrics, making it an attractive option for both beginners and experienced creators. This step-by-step guide outlines essential procedures, from design creation to final curing, ensuring meticulous attention to detail every step of the way. With advancements in DTF technology, it is now more accessible than ever, fostering a vibrant community of enthusiasts eager to share tips and techniques. As you embark on this creative journey, the DTF Process opens up numerous opportunities for artistic expression and business endeavors.