In the evolving landscape of custom merchandise, DTF printing techniques have emerged as a game-changer for artists and designers alike. Known as Direct-to-Film printing, this innovative method efficiently transfers high-quality designs onto various fabrics, significantly enhancing custom apparel printing experiences. The impressive versatility and detail offered by DTF printing benefits artists looking to create vibrant, durable artworks. As we delve into the nuances of the DTF printing process, comparisons with traditional methods, such as DTF vs screen printing, will highlight the advantages and possibilities this technique offers. Join us as we explore how artists can harness DTF printing to maximize their artwork’s potential and redefine their creative expressions.

Direct-to-Film technology, often referred to by its acronym DTF, has quickly become synonymous with modern custom print methods. This advanced printing process allows for the intricate transfer of designs onto fabrics, offering a range of benefits that traditional techniques might not provide. Artists and businesses are increasingly turning towards custom apparel solutions through DTF printing, valuing its efficiency and quality. The unique attributes of this approach make it an attractive alternative for those engaged in textile printing or looking to compare DTF with other prevalent methods, thereby enhancing their production capabilities. Let’s uncover the essentials of this outstanding printing technique and what it means for the future of apparel design.

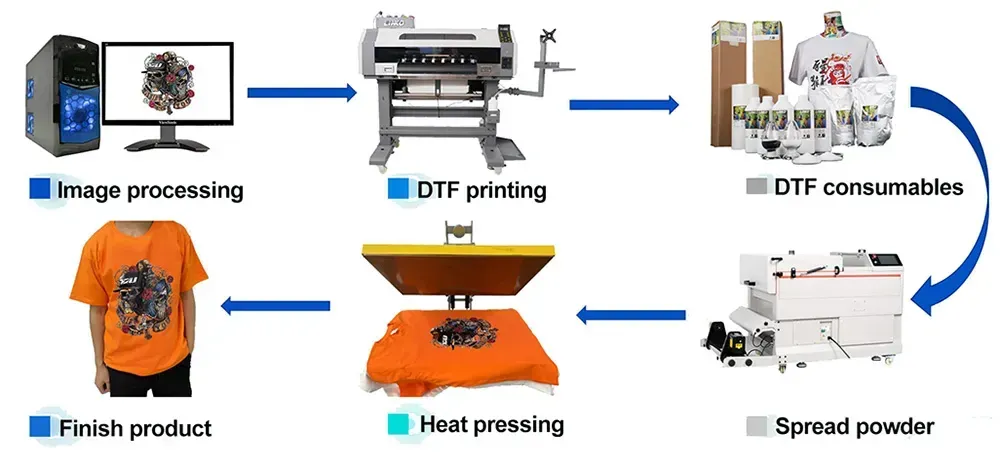

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process starts with creating a digital file of the artwork to be printed. Artists must ensure that their designs are in high-resolution to capture every detail when transferred onto fabric. Once the design is ready, it is printed onto a specialized film using a DTF printer that utilizes high-quality inks. This phase is crucial, as it lays the foundation for color vibrancy and detail in the final print. After printing, the film is covered with a powder adhesive which helps bond the print to the fabric during heat application.

The next step involves precisely heat-pressing the film onto the chosen material. This technique not only transfers the design but also ensures durability, leading to vibrant, long-lasting apparel. Notably, DTF printing stands out for its ability to adhere to various fabric types, from cotton to polyester blends, providing artists significant flexibility in their product offerings. The entire process is designed for efficiency without compromising on the quality of the finished product, making DTF an attractive option for custom apparel printing.

Advantages of DTF Printing Compared to Traditional Methods

When comparing DTF printing to traditional methods like screen printing, several advantages become apparent. For one, DTF printing offers phenomenal color accuracy and detail. While screen printing can be limited by the number of colors and requires setup for each color change, DTF allows for full-color prints, enabling artists to bring intricate designs to life with precision. This capability means artists can reproduce their work authentically, capturing the essence of their artwork without any alterations.

Moreover, DTF printing is significantly more cost-effective for small runs of custom apparel. Traditional screen printing often comes with high setup costs and minimum order requirements, making it less accessible for emerging artists. In contrast, DTF minimizes these barriers by allowing artists to order as little as a single piece, reflecting the growing demand for personalized products in the market. This not only supports individual creativity but also encourages a direct response to consumer preferences.

Custom Apparel Opportunities with DTF Printing

DTF printing opens a world of customization opportunities for artists looking to create unique apparel. Whether designing for special occasions, personalized gifts, or unique clothing lines, DTF technology facilitates a straightforward workflow from concept to finished product. Artists can utilize this method to produce limited-edition items that resonate with their audience, fostering a sense of connection and exclusivity.

Additionally, the ability to quickly adapt designs based on customer feedback allows artists to refine their offerings continuously. This adaptability is particularly advantageous in the rapidly changing fashion landscape, where consumer preferences can shift dramatically. DTF printing allows artists to stay ahead of trends, quickly producing new designs that cater to their target market without the burden of lengthy production times.

Eco-Friendly Innovations in DTF Printing

As the demand for sustainable practices increases, DTF printing has begun to evolve to meet these criteria. Many manufacturers are now producing eco-friendly transfer films and inks that not only provide high-quality prints but are also more environmentally conscious. This shift toward sustainability is particularly important as consumers become more aware of the ecological impact of their purchases.

By incorporating eco-friendly materials, artists can align their brand with ethical values, attracting a customer base that prioritizes sustainability. This innovation not only reduces waste but also encourages responsible production practices within the custom apparel industry. As a result, artists can promote their work proudly, knowing they contribute positively to environmental efforts, which can be a compelling selling point in today’s eco-conscious marketplace.

Best Practices for Optimizing Artwork in DTF Printing

To achieve the best results with DTF printing, artists must focus on optimizing their artwork for this specific technology. This begins with understanding the file preparation process, including choosing the right color profiles and file formats compatible with DTF standards. Proper preparation ensures that the colors remain vibrant and the details sharp when printed, ultimately leading to a higher quality product.

Investing in top-tier materials is another essential best practice. The choice of transfer films and inks directly impacts the final product’s appearance and durability. By ensuring high-quality inputs, artists can produce merchandise that not only impresses customers with its visual appeal but also withstands the test of time. Furthermore, artists should engage in continual learning about advancements in DTF technology and printing techniques to stay updated and maintain a competitive edge in the custom apparel market.

Future Trends in DTF Printing Technology

The future of DTF printing looks promising, with numerous technological advancements on the horizon. Innovations such as larger format printers and more automated processes aim to streamline production, enhancing efficiency and reducing costs for artists and businesses alike. These improvements suggest that DTF printing could redefine the custom apparel landscape, allowing for faster turnaround times and increased versatility in design.

Moreover, as consumer demands evolve, the incorporation of technology into DTF printing is likely to enhance user experience. Features such as easier design software and improved printer interfaces could make it simpler for artists to create and manage their custom products. As the market for personalized apparel continues to grow, staying ahead of technological trends will be crucial for artists seeking to make their mark in a competitive industry.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves printing artwork onto a special film using specialized printers. After printing, the film receives a powder adhesive, which is transferred onto the fabric using a heat press. This method creates vibrant, durable designs on various materials, making it ideal for custom apparel printing.

What are the key DTF printing benefits compared to other methods like screen printing?

DTF printing benefits include superior color accuracy, intricate detail, and cost-effectiveness with lower minimum order quantities. Unlike screen printing, which requires extensive setup and larger batches, DTF allows artists to produce custom apparel on demand, making it more flexible for small businesses.

How does DTF printing technology enhance custom apparel printing for artists?

DTF printing technology enhances custom apparel printing by allowing artists to easily achieve high-quality, vibrant designs with minimal setup costs. Artists can personalize their creations for clients, produce small batches, and respond quickly to market trends, which is essential in today’s competitive landscape.

What materials are suitable for Direct-to-Film printing?

DTF printing is versatile and can be used on various materials, including cotton, polyester, and their blends. This capability makes it an excellent choice for artists looking to produce custom apparel that meets diverse customer needs.

What are some best practices for maximizing artwork potential with DTF printing techniques?

To maximize artwork potential with DTF printing techniques, artists should ensure optimal file preparation for compatibility with DTF standards, invest in high-quality films and inks, and seek educational resources to fully understand the DTF process. These practices greatly enhance print quality and durability.

How does DTF printing compare to screen printing in terms of environmental impact?

DTF printing may have a more favorable environmental impact compared to traditional screen printing by reducing waste associated with large batch productions. Many DTF techniques are evolving to include eco-friendly inks and processes, appealing to environmentally conscious consumers.

| Aspect | Details |

|---|---|

| Definition | DTF printing (Direct-to-Film) is a technique that transfers designs onto fabrics using specialized films. |

| Benefits for Artists | 1. Exceptional color accuracy and detail 2. Cost-effective with low minimum orders 3. Customization and personalization options |

| Market Trends | Increasing popularity in apparel and merchandising with a focus on sustainability and eco-friendly options. |

| Innovations | Advancements in larger printers and automated processes are enhancing productivity and cost-effectiveness. |

| Best Practices | 1. Optimize file preparation 2. Invest in quality materials 3. Embrace learning opportunities |

Summary

DTF printing techniques are revolutionizing the way artists can bring their designs to life on textiles. This innovative method not only enhances the vibrancy and accuracy of colors but also offers a cost-efficient solution with low minimum order requirements, making it accessible for independent creators. With its capacity for customization and personalized products, DTF printing paves the way for artists to engage directly with their customers. As the technology continues to advance, artists adopting DTF techniques will find themselves at the forefront of the printing landscape, poised to expand their creative possibilities and connect with their audience on a deeper level. Embracing these innovative printing methods becomes essential for artists eager to maximize their artwork’s potential in today’s dynamic market.