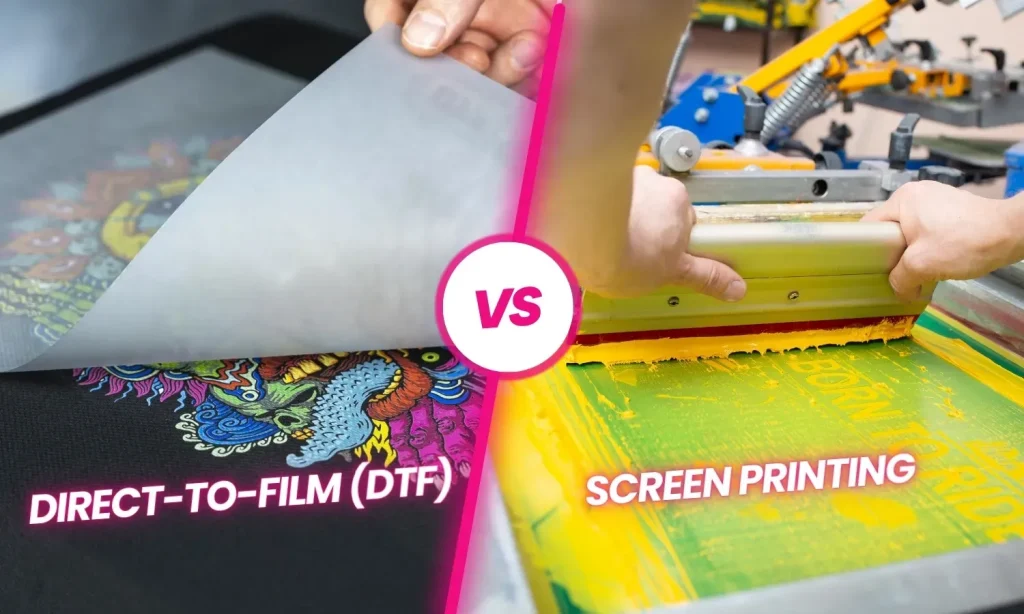

When examining the cost comparison between DTF printing and traditional screen printing, it’s essential to understand how these methods differ in production expenses and overall efficiency. DTF printing cost is notably lower when it comes to equipment and setup, making it an attractive option for newer businesses looking to save money. In contrast, screen printing costs tend to be higher due to the need for multiple screens and setup expenses, which can burden smaller orders. Furthermore, a careful cost analysis of these printing methods reveals that while DTF is swiftly gaining popularity due to its adaptability, traditional screen printing is still favored for large production runs where print quality comparison can justify the higher investment. With both methods having unique advantages, exploring these differences is crucial to making an informed decision for your printing needs.

Understanding the financial implications of modern printing technologies can be pivotal in optimizing business operations. A thorough examination of direct-to-film printing versus classic screen printing unveils key distinctions in costs and efficiencies associated with each technique. Direct-to-film methods offer a promising alternative for businesses seeking lower initial expenses and quicker turnaround times. Meanwhile, conventional screen printing maintains its appeal for bulk orders with economies of scale that serve larger jobs well. By evaluating these alternative terms and their cost structures, businesses can strategically select the right printing method to meet their production demands.

Understanding DTF Printing Costs

DTF printing, or Direct-to-Film printing, offers a distinctive approach that can often result in lower operational costs compared to traditional printing methods. A key advantage lies in the affordability of both the films and inks needed for the process. Since DTF utilizes a transfer medium, businesses can produce intricate designs without the financial burden caused by multiple screens required in traditional methods. This capability allows smaller businesses and startups to engage in custom orders without incurring excessive expenses, thus making DTF printing a financially sensible choice for many.

Moreover, the total cost analysis for DTF printing shows that while the material costs might vary based on the complexity and volume of prints, the investment still remains manageable. The reduced need for extensive setup materials not only lowers the initial investment but also simplifies the production process itself. This sets the stage for DTF printing to thrive in environments where flexibility and rapid output are paramount.

Analyzing Traditional Screen Printing Expenses

Traditional screen printing, however, comes with a different financial profile. The setup costs can be significantly higher, owning to the equipment required to create stencils or screens for each color in a design. This often necessitates an initial capital outlay ranging between $25,000 and $50,000, which can be daunting for newcomers to the industry. Furthermore, businesses that frequently print multi-colored designs find traditional screen printing less economical due to increasing screen and ink requirements. Thus, while it caters well to large production runs, the cost per unit for smaller tasks can become prohibitively expensive.

Additionally, ongoing costs in traditional screen printing can escalate due to the need for replenishing materials and dealing with waste. The inefficiencies tied to lengthy setup times mean that any small batch production can further erode potential profits. This comparative analysis highlights the limitations screen printing faces in fast-paced markets, contrasting sharply with the dynamic options provided by DTF printing.

Material Costs in DTF vs Screen Printing

When examining material costs, DTF printing demonstrates its cost efficiency particularly in smaller orders. The use of specialty transfer films and inks allows businesses to produce vibrant designs without incurring hefty costs associated with screens. What’s more, businesses can manage their inventory better, controlling color quantities more flexibly than in traditional screen printing, where distinct screens must be created for every hue. This translates into financial savings for those who engage in more frequent, customizable printing tasks.

In contrast, traditional screen printing materials often accumulate a higher total cost especially when dealing with multi-colored designs. Each new color requires its dedicated screen, leading to substantial expenditures and waste if designs change frequently. The distinction suggests that while traditional methods benefit larger orders, DTF printing’s streamlined material management offers a more sustainable option, especially for businesses catering to diverse customer demands.

Production Efficiency: DTF vs Screen Printing

Production efficiency is another area where DTF printing shines, significantly impacting cost-effectiveness and turnaround times. Its capacity for quick print jobs on various fabric types without the cumbersome setup of multiple screens means businesses can pivot rapidly, addressing custom orders with ease. This adaptability allows for smaller runs to be produced economically, reflected in lower per-unit costs that are highly attractive to small businesses aiming to meet specific customer requests promptly.

Conversely, traditional screen printing excels in efficiency for larger production runs. With each new screen setup introducing delays, small orders can become a liability as businesses confront high setup times with low output. Ultimately, while screen printing remains advantageous for bulk orders, DTF printing offers compelling advantages in environments where flexibility and rapid output are essential.

Quality Comparison: DTF vs Traditional Printing

Evaluating print quality reveals notable differences between DTF and traditional screen printing. DTF printing provides the capability to deliver intricate, detailed graphics with vibrant colors, ideal for modern design aesthetics. The technology is especially advantageous for designs requiring gradients or multiple hues, making it an appealing choice for brands with a contemporary focus. However, concerns regarding the durability of DTF prints against washing and wear must be addressed as advancements in the technology continue to evolve.

On the other hand, traditional screen printing is often celebrated for its resilience and longevity. The ink adheres directly to the fabric, producing bold colors that resist fading over time, making it a preferred choice for apparel intended for heavy use. This embodiment of durability presents an undeniable strength in traditional methods, especially for clothing designed for everyday wear. Thus, while DTF printing stakes its claim in versatility and vibrant detail, traditional screen printing remains a benchmark for lasting quality.

Environmental Impact: DTF vs Screen Printing

The environmental considerations surrounding printing methods can also influence cost analyses for businesses designing their operations. DTF printing typically uses fewer materials in its process, leading to less waste and a lower overall environmental footprint. This is particularly significant in an era where sustainability is becoming increasingly important to consumers and businesses alike. By minimizing the materials involved, DTF presents a more eco-friendly option, aligning with modern business practices that prioritize sustainability.

In contrast, traditional screen printing often grapples with higher environmental challenges. The process involves the use of chemical inks and the disposal of screens, leading to waste that can harm ecosystems if not managed properly. As businesses consider their long-term impacts and corporate responsibilities, minimizing environmental footprints through methods like DTF can not only contribute positively to sustainability efforts but also resonate well with environmentally conscious consumers.

Frequently Asked Questions

What are the key differences in DTF printing cost compared to traditional screen printing?

The cost comparison between DTF printing and traditional screen printing reveals that DTF printing generally requires a lower initial investment in equipment, starting around $15,000, versus traditional screen printing, which can range from $25,000 to $50,000 due to the need for multiple screens and setup materials. Additionally, DTF printing tends to have lower material costs for smaller runs, making it more economical for custom designs.

How does the DTF printing cost scale with production volume compared to screen printing cost?

DTF printing is particularly cost-effective for smaller batches where the initial setup is minimal, while traditional screen printing becomes cheaper on a per-unit basis as production volume increases. Therefore, for large orders, traditional screen printing usually offers a lower unit cost due to economies of scale.

In terms of print quality comparison, how does DTF printing fare against traditional screen printing?

In a print quality comparison, DTF printing provides vibrant, detailed designs suitable for custom work. However, traditional screen printing is often more favored for its durability and wash resistance. When considering cost, businesses must weigh the quality needs against the printing method’s longevity.

What are the ongoing material costs associated with DTF printing versus traditional screen printing?

The ongoing material costs for DTF printing typically involve DTF films and inks, which can remain competitive for limited runs. In contrast, traditional screen printing incurs higher material costs due to the necessity of multiple screens for multi-colored designs, making it less economical for smaller jobs.

How does equipment setup differ in terms of cost analysis for DTF printing and traditional screen printing?

Cost analysis shows that DTF printing’s equipment setup is simpler and less costly, requiring only a DTF printer and basic supplies. Traditional screen printing demands a more complex setup including multiple screens and exposure units, increasing the initial investment significantly.

What environmental factors should be considered in the cost comparison of DTF printing vs traditional screen printing?

When comparing costs, environmental factors play a role as DTF printing produces less waste with fewer materials required. Traditional screen printing, on the other hand, faces greater environmental concerns due to the use of chemicals in inks and the disposal of screens, impacting its overall sustainability and increasing hidden costs.

| Aspect | DTF Printing | Traditional Screen Printing |

|---|---|---|

| Initial Equipment Cost | Starting at $15,000; lower initial investment, minimal setup needed | Ranges from $25,000 to $50,000; higher due to multiple screens and additional equipment |

| Material Costs | Affordable per-item costs, competitive for smaller runs | Escalating costs due to the need for multiple screens for different colors |

| Production Efficiency | Quicker turnarounds; ideal for small batches and custom designs | Slower setup but cost-effective for larger runs as unit costs decrease |

| Print Quality and Longevity | High-quality prints with vibrant colors; concerns about wash resistance | Durable prints that resist fading, particularly on darker fabrics |

| Environmental Impact | Lower impact with less waste and fewer materials | Higher impact due to chemicals used and waste from screens |

Summary

Cost comparison between DTF printing and traditional screen printing reveals critical differences in equipment costs and production efficiencies that significantly impact business decisions. DTF printing provides a more affordable upfront investment, making it an attractive option for small businesses and custom projects, whereas traditional screen printing, despite its higher initial costs, offers efficiency in larger production runs. In considering the longevity and environmental impact, DTF printing boasts lower waste production, while traditional screen printing excels in durability. Ultimately, the decision hinges on specific business needs, encompassing budget, design requirements, and production volume.