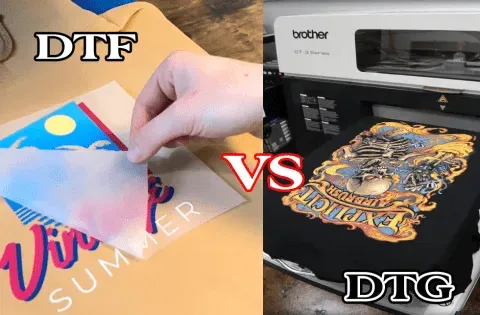

When it comes to apparel decoration, the debate between DTF vs. DTG often captures the attention of business owners seeking the best printing solutions. Direct to Film (DTF) and Direct to Garment (DTG) represent two innovative methods that have revolutionized garment printing, each with distinct advantages tailored to specific market needs. DTF printing offers exceptional versatility, accommodating a variety of fabrics, while DTG printing is renowned for its exceptional detail and vibrant color output on cotton materials. Understanding the key differences between these methods allows businesses to make informed decisions, ensuring optimal results for their custom apparel projects. In this article, we will delve into the intricacies of both DTF and DTG printing, equipping you with the knowledge needed to select the ideal technique for your business requirements.

The realm of garment decoration has witnessed remarkable innovations, with Direct to Film (DTF) and Direct to Garment (DTG) emerging as leading printing technologies. Sometimes referred to as film transfer printing, DTF caters to a diverse array of fabric types, making it a versatile choice for businesses aiming to expand their offerings. Conversely, DTG, or direct-to-fabric printing, utilizes advanced inkjet techniques to deliver intricate designs directly onto textiles, predominantly cotton. By examining alternative definitions and applications of these methods, we can better appreciate their unique qualities and how they stack up against each other in the competitive world of textile printing. This exploration will shed light on the best fit for your artistic vision and business goals in apparel production.

The Basics of DTF and DTG Printing

Direct to Film (DTF) and Direct to Garment (DTG) are two prominent methods of garment printing that have taken the textile industry by storm. While both techniques aim to transfer designs onto fabric, their processes and applications vary significantly. DTF printing works by creating vibrant, high-resolution designs on a special film that are then heat-pressed onto garments. This method accommodates a wide range of materials, making it ideal for businesses looking to diversify their product offerings. Conversely, DTG printing utilizes specialized inkjet technology to print directly onto fabric, primarily cotton, allowing for stunning, full-color designs that suit short runs and unique customizations.

Understanding the intricacies of each printing process is crucial for any apparel business. DTF printing is especially renowned for its efficiency and adaptability, enabling quick setup and production for various fabric types, including synthetic blends. On the other hand, DTG printing shines when it comes to intricate designs and vivid color reproduction, making it a favorite for custom t-shirts and small orders. By exploring the strengths and weaknesses of both methods, businesses can better align their production strategies with consumer demands.

Comparing Durability and Print Quality

When considering garment printing options, durability and print quality are paramount. DTF printing generally outperforms DTG in terms of resilience, especially when subjected to multiple washes. Prints created through the DTF method maintain their integrity and color vibrancy, even on challenging fabrics like polyester. This quality makes DTF an excellent choice for businesses focusing on sportswear or activewear, where fabric durability is a priority. In contrast, while DTG can produce exceptional detail and color depth, the prints may fade or crack over time if not cared for properly.

However, DTG printing remains a strong contender for high-detail designs that require nuanced color gradients and complexity. The ability to create vibrant, multi-colored patterns directly on cotton fabric allows for personalization at its finest. Whether it’s a personalized gift or a limited-edition fashion line, DTG facilitates an artistic approach to garment decoration. Ultimately, your choice should reflect your target market’s expectations regarding longevity and aesthetic appeal.

Cost Implications of DTF vs. DTG

One of the most significant factors influencing the decision between DTF and DTG printing is cost. DTF printing is often seen as the more budget-friendly option due to its lower setup costs and the ability to produce high-quality prints on various materials. For businesses anticipating larger production runs, DTF’s efficiency can lead to considerable savings over time, allowing for better inventory management and pricing strategies that can appeal to a broader customer base.

DTG printing, however, usually involves a higher initial investment in specialized equipment and ongoing maintenance fees. While this method can be more expensive for small batches, it becomes economically viable for businesses focused on high-end, custom prints that allow for greater margins. Understanding these costs and your business’s printing demands will enable you to make a financially informed choice, which is crucial for sustainable growth in the competitive apparel market.

Material Compatibility in Printing Techniques

The versatility of material compatibility is another key differentiator between DTF and DTG printing. DTF printing allows for flexibility across a wide range of fabrics, including cotton, polyester, and blended materials. This capability is essential for brands looking to create a diverse product line. For example, clothing manufacturers who wish to offer a variety of styles, from cotton t-shirts to polyester athletic wear, will find DTF particularly advantageous for its ability to adapt to different material needs.

In contrast, DTG printing predominantly works best with 100% cotton fabrics, which can limit design initiatives for brands wishing to expand their offerings. While advancements in DTG technology are evolving to accommodate more fabric types, the depth of compatibility remains a crucial consideration when deciding on a printing method. Businesses aiming to serve a broader audience should weigh their options carefully, focusing on the materials they intend to utilize in their garment production.

Environmental Impact of Printing Methods

Environmental considerations are becoming increasingly significant in the apparel printing industry. Both DTF and DTG printing primarily utilize water-based inks that are more sustainable than traditional solvent-based inks. This eco-friendly aspect is a crucial selling point for businesses aiming to appeal to environmentally conscious consumers. However, it is essential to assess the entire production process, including the sourcing of materials and waste management practices, to ensure that your chosen printing method is genuinely green.

Additionally, as businesses seek to promote sustainability, they may want to consider the impact of their printing choices on overall carbon footprints. DTF printing’s ability to work on a variety of fabric types means reduced waste as less material is discarded in the production process. In contrast, DTG, while not as materially flexible, allows for efficient single-piece production that minimizes overproduction. Ultimately, aligning your printing practices with sustainable initiatives will enhance your brand’s reputation and resonate well with conscious consumers.

Deciding Factors for Your Business

When choosing between DTF and DTG printing, several key factors should inform your decision-making process. Understand your target audience, the types of garments you want to produce, and your specific printing goals. If your business leans towards high-volume production with diverse fabric compatibility, DTF might be the ideal choice. Alternatively, if you specialize in unique designs on cotton apparel, DTG’s capabilities could better serve your artistic intentions.

Moreover, evaluating your budget, operational capabilities, and long-term business strategy will further clarify your path forward. Whether you opt for the efficiency and flexibility of DTF or the detailed artistry offered by DTG, ensuring that your choice aligns with your brand philosophy and market needs is critical to achieving sustainable success and customer satisfaction.

Frequently Asked Questions

What is the key difference between DTF printing and DTG printing?

The primary difference between DTF and DTG printing lies in their application processes. DTG printing directly applies ink onto the garment fabric using an inkjet printer, making it ideal for detailed designs on cotton. In contrast, DTF printing involves transferring printed designs from a special film to various fabrics through heat, showcasing versatility with material compatibility.

Which is more versatile for garment printing, DTF or DTG?

DTF printing is generally more versatile compared to DTG printing. It can be used on a wide range of materials, including cotton, polyester, and blends, whereas DTG primarily works best on cotton fabrics. This material compatibility allows DTF to cater to a broader market.

How does the durability of DTF printing compare to DTG printing?

DTF printing typically offers greater durability than DTG printing. DTF prints can withstand multiple washes without significant fading, while DTG prints may fade more quickly over time, especially if not cared for properly. Therefore, for longevity in garment printing, DTF is usually the better choice.

Is DTG printing suitable for large production runs?

DTG printing is not as efficient for large production runs due to its higher setup costs and longer printing times. Instead, DTF printing is more efficient for bulk orders, providing faster setups and lower operational costs, making it the preferred method for larger print jobs.

Which printing method provides better print quality, DTF or DTG?

DTG printing is often recognized for its superior print quality, particularly with detailed, multicolored designs, offering vibrant colors and intricate clarity. However, DTF also produces quality prints and excels in vibrant designs, particularly for solid patterns, but may not achieve the same level of detail as DTG.

What are the cost implications of choosing DTF vs. DTG printing?

When comparing costs, DTF printing generally requires a lower initial investment and operational costs, making it appealing for businesses anticipating larger production runs. Conversely, DTG printing often involves higher setup costs and is more economical for small runs, but the machinery can be costly.

| Attribute | DTG Printing | DTF Printing |

|---|---|---|

| Material Compatibility | Best with cotton products; limited options. | Versatile; works on cotton, polyester, and blends. |

| Durability | May fade after washes; requires proper care. | Better longevity and durability against washing stress. |

| Print Quality | High-quality with vibrant colors, ideal for complex designs. | Produces quality prints but excels in solid patterns and vibrant colors. |

| Cost Considerations | Higher initial investment but economical for small batches. | Lower setup costs; ideal for larger production runs. |

| Environmental Considerations | Utilizes water-based inks; requires scrutiny of inks used. | Also uses water-based inks but check specific materials used. |

Summary

In the discussion of DTF vs. DTG, understanding the specific needs of your business is crucial in choosing the right printing method. Direct to Garment (DTG) is ideal for businesses focusing on detailed, custom designs primarily on cotton fabrics. Alternatively, Direct to Film (DTF) offers more versatility, allowing prints on various materials, including blends, along with improved durability. By considering factors like material compatibility, durability, print quality, and cost, companies can make informed decisions that cater to their operational strengths and creativity, ensuring customer satisfaction. Ultimately, both methods are valuable assets in the modern printing landscape, and the choice should align with your business goals and target audience.